|

Only fools will go… step 3 - The problems start I now have a movement with installed going

train up to the escape wheel and anchor. It seems very strange to me that

when the escapement turns the anchor can get in a state where it wobbles back

and forth, but doesn’t lock to the sides. A visit to my tutor shows me how

this should look; the anchor should lock conclusively to both sides. Not what

I am seeing at all. Exact measuring on an optical table shows that I have

drilled the placement for the escapement wheel too far from the anchor, a

manufacturing error. It is interesting to note that the geometry of the

pallets and escape wheel teeth allows a completely blocking position at a

certain, too large, distance between escapement wheel and anchor. This seems

counter-intuitive, but is born out using paper cutouts of the escapement

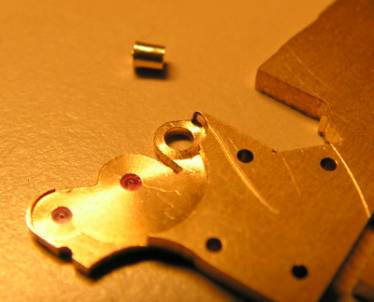

wheel and anchor enlarged 20 times. What to do? I decide not to completely remake the

plate and bridges at this point, but to drill out the existing holes, fill

with a brass plug and try to aim correctly when drilling this time. Here some

pictures of this work.

Plug in place ready to be pressed in. I am

using the jewelling press to press this in and keep control.

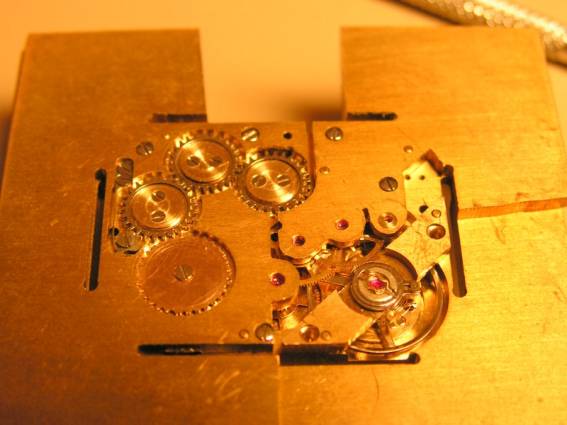

After turning down the excess on the lathe

facing plate, another try at drilling at the correct position.

After this detour things are looking

better. And here it is, the first picture with the

balance mounted… and what you can’t see, it is turning. The amplitude is very

weak, but it is self-sustaining. I am ecstatic!

But now, how to get the amplitude up? The

possibilities are multitude. My tutor says if the going train is not perfect

there is no way it will work. When wound at the barrel the going train should

stop only after reversing. I am not seeing that. I put all the parts through

the ultrasonic cleaner to be sure that there are no shavings or dust from all

the machining work hiding somewhere and causing problems. Reassembly,

checking all shakes and oiling improves the going train so that it really

does stop only after reversing, but the balance amplitude shows no

significant improvement. I am slow to see it, but my balance is

standing at a slight angle. This appears to be causing the hairspring to touch

on one edge of the balance bridge. I did try and cause the hairspring to not

touch, but that is not the solution and messed up my hairspring some. I see

that once messed up a hairspring can cost one days of work. In the end I realize that the error happened

very early on. I first drilled the holes for the incablock using a standard

twist drill, not having a better drill near that diameter. Of course the hole

ended up slightly triangular. In afterthought I remember that this is just

about always the case with such drills. I then brought the hole up to full

diameter on the lathe, but with the triangular hole I lost the real center. I

should have used a good drill to assure good centering, as I had to enlarge

the hole on the lathe anyway. That way I would have not lost the centering.

All the other holes I have drilled with the special hard-metal drills that

are made for making the holes in printed circuit board production. They cut

clean and perfectly. And the marked drill size is the size of the hole it produces,

not the size of the drill. They are a joy to use, but do break quite easily.

My tutor tells me that for precise watch work even these drills are too long

and can wander. Drills for watch work should be more like 5 mm long maximum I

am told. What to do now? I hate to admit it, but

for the moment I have removed the steady pins and with the leeway around the

screws am able to move the bridge enough to have the balance stand straight.

The balance amplitude is better, but still not good. The balance frequency is

also strangely off by about 25%. How can that be? Give me a little time to find a clean(er)

solution for positioning the balance bridge and for another visit to my tutor

to elucidate some more possible reasons for insufficient amplitude and wrong

frequency. -----------------.....-----------------.....-----------------.....-----------------.....-----------------

Yes, things are just fine now, the reason

for the frequency and amplitude problem totally unexpected, i.e. not

something I did terribly wrong. It was actually just a passing remark of my

tutor that set me on the right track. He mentioned once that the 2824 had

been made both in 4Hz and 3Hz versions with identical wheel placements. I

realised that was exactly the amount I was off. For 15 seconds movement of

the second hand it was taking 20 seconds. When this finally dawned on me I

quickly opened up another movement to extract its balance/hairspring

assembly. Placing them side-to-side, there was no apparent difference in the

balance except one was nickel and the other glucydur, but the hairsprings

were not the same. So I decided to install the new one and see what happens.

And what happened was that the timing is right and the balance amplitude is

OK, after a little fiddling to get the pallet draw right. One of the movements that I canabalised

for this project must have been a 3Hz movement. Which means that I must also

have an escape wheel/seconds wheel pair for 3Hz too. Maybe that was the

seconds wheel who's misery I ended by stepping on it while I was trying to

find it on the floor. Since then my strategy for finding pieces that have

found their way to the floor has changed to first inspecting the places where

I want to put my feet. There is still a pretty big difference in

amplitude depending on the position, between 200° and 290°, and I realise

that I should be getting over 300°, but I am going to wait to try to find

that until I am finished drilling and filing. I still suspect brass chips or

dust hanging out around the bearings as my biggest problem. Once that

"dreck" has found its way into the oil, however tiny that amount of

oil might be, only a real cleaning will help. I think the "clean"

way to do this is to have a room for machining, the "dirty room",

and a room for assembly, the "clean room". That way one would have

a chance to keep things as clean as one should. When, however, everything is

happening on the same benchtop you can be as careful as you want. It is still

not enough.

And, BTW, I did find a cheat for re-positioning

the balance bridge without lots of work. I turned the steady pins slightly

conical, the top end remaining the original diameter. The radius at the

position on the pin corresponding to the top surface of the plate is down

0.2mm. I then bent the pin 0.2mm in the direction needed. The pin remains

stable and at the same time the bridge still sits perfectly flat on the plate

and is well positioned. Although the top of the pin is now at a slight angle

the difference is so small that it is invisible. It seems to work fine, but

please don't tell anyone. I am now preparing to finish the keyless

works to be able to set the time from the crown. This is the part of the

movement that I am most worried about. It has the largest portion of my

design, the smallest portion from ETA. Then it will be time to make the

hands. Don Copyright © 2005 Donald W. Corson |